This procedure decreases the brittleness of the steel. Pretty much nothing but charcoal.

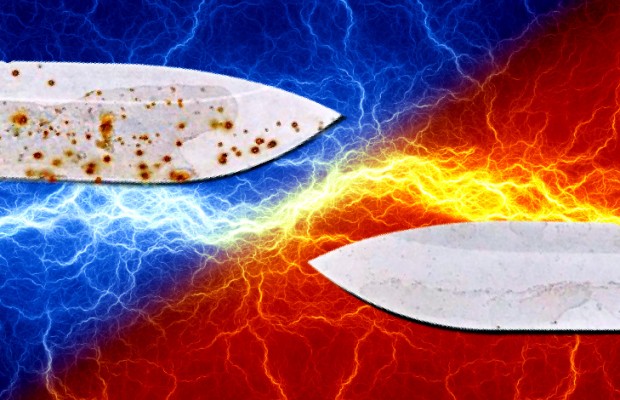

Heat treat and quenching a knife blade.

How to heat treat a knife. Knife Making - How To Heat Treat A Knife Super Simple DIY heat treating. The 4 steps you NEED to know. More info belowBeginner knife making steel video.

How to Heat Treat a Knife simplest Method Possible Step 1. For this simple heat treating method you wont need much. Here I am using natural.

Quite obviously you are also going to need a forge of sorts. For this bare bones heat treat there is no. Normalize With this step you recreate a uniform or normalized state within the steel so that it becomes more.

Quench After heating quickly plunge the steel into a can of oil and move it back and forth in a slicing motion. Heat Treating Step-by-Step 1 Heat the Blade. Start the forge and use the tongs to place the knife inside.

Only the blade section of the knife needs. Dim lighting is helpful in judging the color of the blade as it heats. The goal is to attain an orange.

3 Critical Temperature. Heat Treating Knives Step 1. Surface and Edge Preparation.

The heat treating method is the same for knives made from forging or stock. Normalizing involves bringing the unhardened blade to critical temperature a few times to stabilize. I used this.

How to heat treat a knife in the absolute simplest easiest laziest way possible. Pretty much nothing but charcoal and a blowdryer. Pretty much nothing but charcoal.

That said use this as a guide to heat treating but not a verbatim blow-by-blow. You must refer to the directions for heat treating your particular type of steel. The basic process is as follows.

Heat your forge up to the critical point for your steel 1450F depending on your steel. Using a pair of industrial sized tongs stick your knife in the heat until its a consistent cherry red sometimes 10-15 minutes. You can bring it out of the heat.

Tempering includes warming the knife to lower temperature levels 400-degree variety a number of times. This procedure decreases the brittleness of the steel. There are likewise other procedures that can be done such as Normalizing and Cryo Treatment.

Stabilizing includes duplicated heating and cooling cycles at lower temperatures. Hardening a knife makes it hold a sharp edge better. Its done by heating the knife to critical temperature and cooling rapidly in a quenching liquid usually oil.

Tempering Increases toughness Tempering a knife increases its toughness by making it less brittle. Looking for the recipe or step by step ramp hold instructions for heat treating and tempering 440C Stainless Steel and CPM154 Stainless Steel Knife blades t. Virtually any knife steel can be heat treated with or without cryo depending on the hardening temperature that is selected.

However higher hardness levels can be achieved when using cold treatments see the chart for AEB-L below where the minimum temperature is labeled as LN2 cryo freezer a household freezer or room temperature no cold treatment. Temperature controls how much carbon is put in solution and with 1095 there is enough carbon to cause problems if one doesnt have control of temperatures to manage it. With 1095 and no control its very easy to put too much carbon in solution or.

Yes steel changes color as it is heated. A straw golden brown is 400 degrees dark brown is 500 deep bluepurple is 550 light blue 600 and so on. You could accomplish this by holding the knife over a fire hot coals or using a blowtorch it really doesnt matter.

When the steel hits that golden straw color you know you nailed it. Here he is using tool wrap high temperature heat treat stainless foil. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works.

How to Easily Heat Treat 1095 High Carbon Steel for Knife Making. This video is part of The Complete Online Guide to Knife Making. In this video we demonstra.

Heat treatment refers to the process where softer steel is hardened so that it stands up to use as a knife blade. To heat treat steel I heat it up beyond cherry red to glowing red. For 1095 steel as this blade is this occurs at a temperature above 1335 F.

Heat treat and quenching a knife blade. Temper the knife blade by setting an oven to 400 degrees Fahrenheit and allowing the blade to heat for 20 to 30 minutes.