Alumina can be produced in a range. They are a very important structural ceramic that is newly developed next to alumina ceramics.

However this ceramic can be combined with other materials to manufacture any products and that combination would be called composite or alumina-based materials.

Is alumina a ceramic. Is AluminaAl2O3 a ceramic or a composite. Alumina is a ceramic. The primary feature that determines this categorization is the fact that aluminum and oxygen share ionic bonds.

This makes the material brittle and electronically insulating. Is silicon carbide a ceramic. Silicon carbide mainly consisting of SiC is the most corrosion-resistant ceramic used in mechanical seals and pump parts.

Yes Al2O3 Alumina is a ceramic. Ceramic is basically an inorganic solid made up of either metallic or non-metallic compounds. They are shaped and then hardened by heating to high temperatures.

Ceramic is basically an inorganic solid made up of either metallic or non-metallic compounds. Alumina Aluminum Oxide or Al 2 O 3 is an excellent electrical insulator and one of the most widely used advanced ceramic materials. Additionally it is extremely resistant to wear and corrosion.

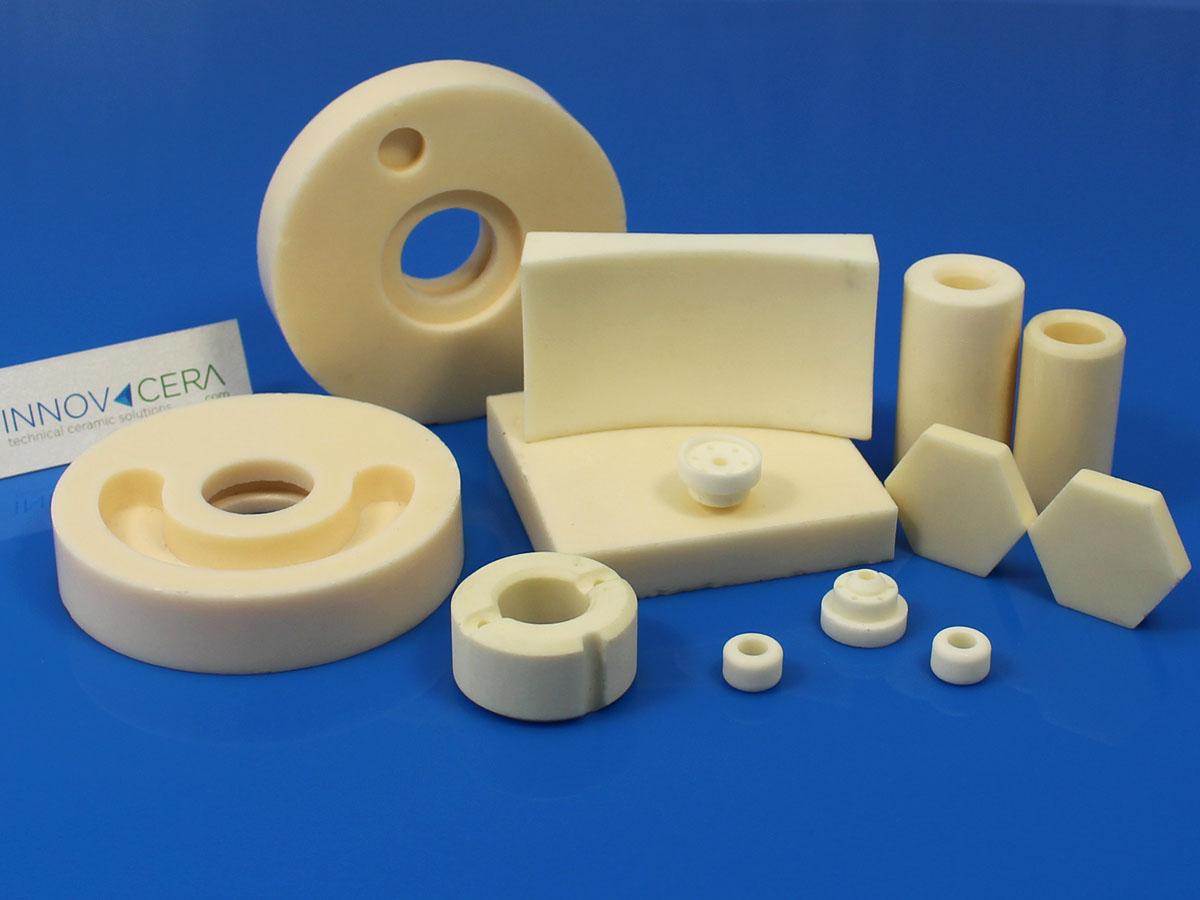

Alumina components are used in a wide range of applications such as electronics pump components and automotive sensors. Since alumina ceramic comes with an amazing property combination it encourages you to create a plethora of ceramic products. Thats why you can find zirconium and alumina ceramic combinations.

Alumina is a very hard ceramic and is excellent at resisting abrasion. It is ideal for wear-resistant inserts or products. Alumina is commonly used as a high temperature electrical insulator particularly the higher purity grades which offer better resistivity.

Alumina ceramics is a widely used ceramic because of its superior performance in modern society has been more and more widely used to meet the needs of daily and special performance. Alumina ceramic technology is maturing but some of the indicators have yet. Solid-phase sintered alumina ceramic materials are of high purity 999 by weight and are mainly used in high temperature environments and require excellent corrosion resistance such as transparent aluminum tubes for high pressure sodium lamps.

A coating film is required on the surface of the ceramic. The coating film is to apply a filter layer. The material used depends on the pore size100 nm is 99995 alpha-alumina 50-30 nm is 9999 zirconia and 10 nm is 9995 Titanium oxide.

The most important and wide-ranging use of alumina is in the field of ceramics. As an Insulating Material The dielectric and excellent thermal shock properties of Alumina make it an excellent choice as an insulating material. For applications in very high frequencies high purity dense alumina fired at temperatures above 1600C is generally used.

Alumina is the most well-known and most commonly used fine ceramic material. It has the same sintered crystal body as sapphire and ruby. It has been used for decades in electrical components for its high electrical insulation and is widely used in mechanical parts for its high strength and corrosion- and wear-resistance.

Alumina Ceramics Al₂O₃ Alumina or Aluminium Oxide Al 2 O 3 is a major engineering material. It offers a combination of good mechanical properties and electrical properties leading to a wide range of applications. Alumina can be produced in a range.

Known as alpha alumina in materials science communities or alundum in fused form or aloxite in the mining and ceramic communities aluminium oxide finds wide use. Annual world production of aluminium oxide in 2015 was approximately 115 million tonnes over 90 of which is used in the manufacture of aluminium metal. Alumina is arguably the most widely-used advanced ceramic material and it is made from the naturally-occurring ore called bauxite by implementing the process of Bayer extraction.

The chemical compound of bauxite contains both oxygen and aluminium molecules. Alumina ceramic Aluminum Oxide or Al2O3 is an excellent electrical insulator and one of the most widely used advanced ceramic materials. Alumina components are used in a wide range of applications such as electronics pump components and automotive sensors.

In general zirconia ceramics have the advantages of high hardness good wear resistance high toughness low friction coefficient and good corrosion resistance. They are a very important structural ceramic that is newly developed next to alumina ceramics. Due to its good properties such as its fracture toughness is higher than alumina ceramics zirconia ceramic structural parts have received more and.

The Alumina Al203 is a popular advanced ceramic oxide used for a number of applications such as catalysts chemicals absorbents microelectronics aerospace industries and high-technology fields. However this ceramic can be combined with other materials to manufacture any products and that combination would be called composite or alumina-based materials. This finest Alumina ceramic.